Model:

P198-S20

Material Name:

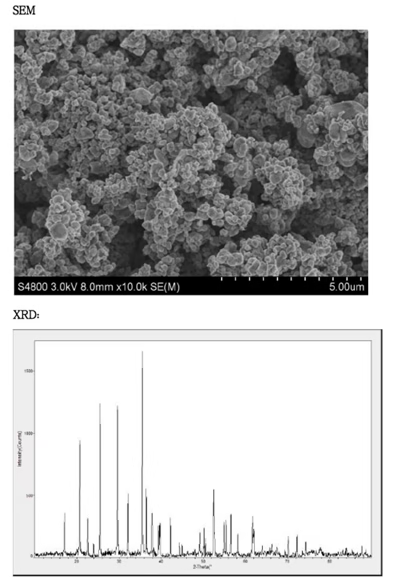

Lithium Iron Phosphate Cathode Material Powder

Standard Package:

150g/bottle, 700g/bottle

Application:

Battery Cathode Material

Overview:

It features excellent electrochemical performance, including good processability, high compaction density, high capacity, and low internal resistance. It is mainly used in the production of lithium-ion batteries.

Main Parameters:

| Test Item | Unit | Specification | Typical Value | ||

|---|---|---|---|---|---|

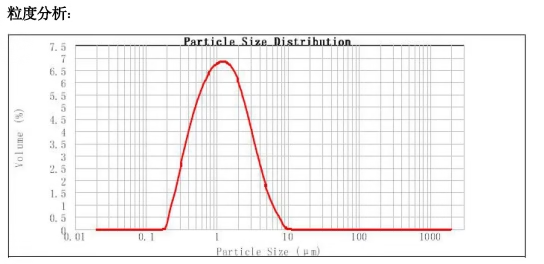

| Physical Properties | Particle Size Distribution | D10 | um | ≥0.25 | 0.39 |

| D50 | um | 1.0±0.5 | 1.08 | ||

| D90 | um | ≤10 | 4.24 | ||

| Carbon Content | % | 1.50± 0.2 | 1.48 | ||

| Specific Surface Area | m2/g | 11.5± 2.0 | 12.3 | ||

| Tap Density | g/cm3 | 0.8±0.2 | 0.66 | ||

| Moisture Content | ррm | ≤1000 | 764 | ||

| Electrochemical Properties | 0.1C Discharge Capacity (2.5–3.7 V) | mAh/g | ≥154 | 159.1 | |

| 0.1C Initial Coulombic Efficiency (2.5–3.7 V) | % | ≥95 | 97.82 | ||

Material Characteristics: