Model:

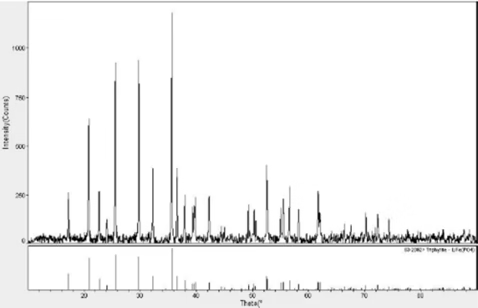

P198-S13

Material Name:

LiFePO4 Carbon-Coated Lithium Iron Phosphate Cathode Material

Standard Package:

150g/bottle, 700g/bottle

Application:

Cathode Material for Lithium-ion Batteries

Overview:

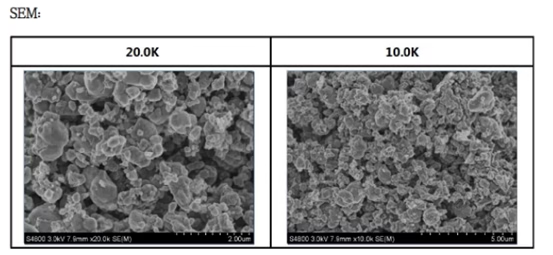

It features excellent processability, high tap density, high capacity, and low internal resistance, making it primarily suitable for lithium-ion battery manufacturing.

Main Parameters:

| Test Item | Unit | Standard | Typical Value | ||

|---|---|---|---|---|---|

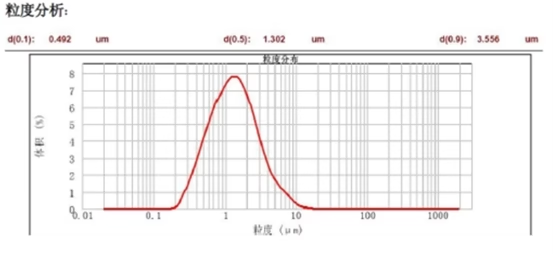

| Physical Properties | Particle Size Distribution | D10 | um | ≥0.25 | 0.492 |

| D50 | um | 0.8~1.8 | 1 .302 | ||

| D90 | um | ≤10 | 3.556 | ||

| Carbon Content | % | 1.45± 0.2 | 1.48 | ||

| Specific Surface Area | m2/g | 12±2 | 12.3 | ||

| Tap Density | g/cm3 | ≥0.6 | 0.72 | ||

| Moisture Content | ррm | ≤1000 | 800 | ||

| Electrochemical Properties | 0.1C Discharge Capacity (2.5–3.7 V) | mAh/g | ≥154 | 164 | |

| 0.1C Initial Coulombic Efficiency (2.5–3.7 V) | % | ≥95 | 98 | ||

Material Features:

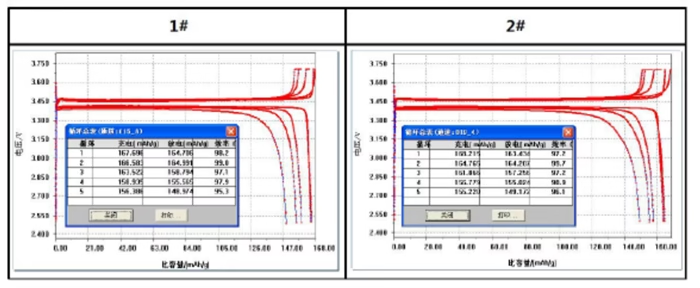

Coin Cell Test Data:

| 0.1C 3.7V | Constant Current - Constant Voltage (CC-CV) Charging | Cutoff current |

|---|---|---|

| 0.1C 2.5V | 0.1C 2.5V |

| Battery ID | 0.1C | 0.1C 2 times | 0.3C | 0.5C | 1C |

|---|---|---|---|---|---|

| 1# | 164.7 | 164.9 | 158.7 | 155.56 | 148.9 |

| 2# | 163.4 | 164.2 | 157.2 | 155.02 | 149.1 |

Full Cell Application:

Battery Design Scheme (Model: 18650EC)

| Cathode P198-S13 | Anode-158-C | Nominal Capacity (mAh) | Electrolyte Volume (g) | |||||

|---|---|---|---|---|---|---|---|---|

| Design Specific Capacity (mAh/g) | Areal Density (g/m²) | Compaction Density (g/cm³) | Design Specific Capacity (mAh/g) | Areal Density (g/m²) | Compaction Density (g/cm³) | Anode Excess | 1650 | 6 |

| 142 | 325 | 2.3/2.4 | 335 | 145 | 1.5 | 10% | ||

For the P198-S13 material, a compaction density in the range of 2.3–2.4 g/cm³ is recommended, with a designed specific capacity between 140–145 mAh/g.

Recommended electrolyte references include Capchem LBC3229B and TC-E80·22.

Slurry Formulation:

| Material Type | C | SP | SBR+CMC | Solid Content (%) | Viscosity (mPa·s) | Fineness (μm) |

|---|---|---|---|---|---|---|

| 158-C | 95.5% | 1.5% | 1.8%+1.2% | 46.0% | 3600 | 30 |

| Material Type | LFP | SP | PVDF(5130) | Solid Content (%) | Viscosity (mPa·s) | Fineness (μm) |

| 198-S13 | 93.0% | 4.0% | 3.0% | 50.0% | 4470 | 12 |

The binders used for 198-S13 are PVDF (5130) and HSV900, with a recommended addition amount of 3.0–4.0%.

Cell Formation Data:

| Compaction Density | Initial Coulombic Efficiency | 1C Discharge Capacity (mAh ) | 1C Cathode Utilization (mAh/g ) | Internal Resistance mΩ |

|---|---|---|---|---|

| 2.3 | 90.0% | 1688 | 143.7 | 16.5 |

| 2.4 | 90.5% | 1715 | 144.2 | 15.0 |