Model:

Material Name:

Application:

Standard Package:

Overview:

Main Parameters:

| Test Item | Unit | Specification | Typical Value | Testing Method |

|---|---|---|---|---|

| D10 (um) | um | ≥5 | 6.55 | MasterSizer 2000 |

| D50 (um) | um | 12-18 | 14.63 | |

| D90 (um) | um | ≤35 | 28.85 | |

| Tap Density | g/am3 | 1.0-1.2 | 1.10 | Tap Density Tester |

| Specific Surface Area | m2/g | 1.0-3.0 | 1.65 | BET Method |

| Moisture Content | % | ≤0.20 | 0.07 | Gravimetric Method |

| Ash Content | % | ≤0.10 | 0.02 | Gravimetric Method |

| Fe Content | ppm | ≤50 | 10.1 | Atomic Absorption Spectroscopy |

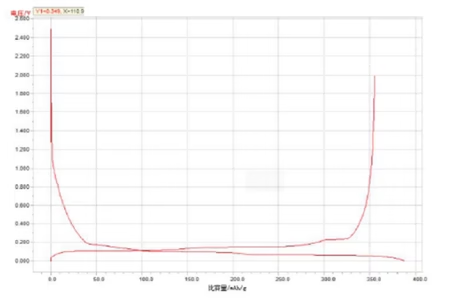

| Specific Capacity | mAh/g | ≥355 | 358.4 | Simulated Cell Test |

| Initial Coulombic Efficiency | % | ≥92.0 | 93.2 | Simulated Cell Test |

Electrochemical Testing:

Test Conditions:

Binder system: SBR/CMC

Composition ratio (MAG-106 : SP : SBR : CMC) = 91 : 5 : 2.4 : 1.6

Electrolyte components: LiPF6 / EC : EMC

Discharge: 0.1C down to 0.001 V

Charge: 0.1C up to 2.0 V, cutoff current 0.01C

Recommended Usage Guidelines:

Design Capacity:

The anode design capacity is 350 mAh/g.

For consumer lithium-ion batteries, an excess ratio of 6–8% is recommended;

for power-type lithium-ion batteries, an excess ratio of 10–15% is suggested.

Tap Density:

The electrode tap density (first roll) is 1.55 g/cm³.

Actual tap density should be controlled between 1.50–1.65 g/cm³, depending on battery structure and performance requirements.

Cycle Performance:

For cylindrical or prismatic aluminum-case consumer lithium-ion batteries:

≥ 80% capacity retention after 800 cycles at 1C charge/discharge rate.

For pouch-type power batteries:

≥ 80% capacity retention after 500 cycles at 1C charge/discharge rate.