Model: MR-XQM-0.4L

Product Introduction

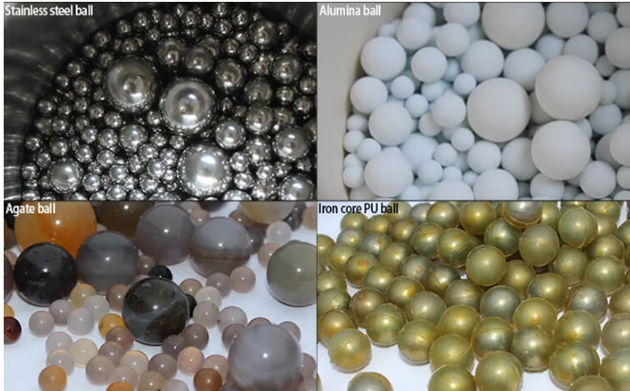

Optional Ball and Jar

Working principle:

Specifications:

| Model | Planetary Ball Mill Machine MR-XQM-0.4L |

|---|---|

| Grinding tank volume (L) | 100ml*4 |

| Grinding tank material | Optional Stainless Steel, hard steel, zirconia, agate, corundum, tungsten carbide, nylon, polyurethane, PTFE, etc. |

| Grinding media | Optional Stainless steel, agate, zirconia, corundum, etc. |

| Maximum loading per tank | Material and grinding medium does not exceed two-thirds of the volume |

| Feeding material size | Soil material ≤ 10 mm, other materials ≤ 3 mm |

| Discharge material size | Min 0.1um |

| Rotating speed | Revolution 45-435 r / min, Rotation 90-870 r / min |

| Speed ratio (revolution: rotation) | 1:2 |

| Speed mode | Frequency, programmable stepless speed regulation, manual, automatic timing forward and reverse |

| Transfer method | Gear drive |

| Working Voltage | 220V |

| Motor power and variable frequency power | 0.75Kw |

| Way of working | Two or four cans work at the same time |

| Maximum continuous operating time | 72hours |

| Machine Size | 500*300*340mm |

| Weight (not include Jars and Ball ) | 30kg |

| Model | Power supply | Motor power Converter power | Operating time setting (min) | Positive and negative alternating operation time(min) | Adjustable speed Revolution (rpm) | Adjustable speed Rotation (rpm) | Noise <db |

|---|---|---|---|---|---|---|---|

| XQM-0.2 | 220V 50HZ | 0.75KW | 1-9999 | 1-999 | 30-335 | 70-670 | 60db |

| XQM-0.4 | 220V 50HZ | 0.75KW | 1-9999 | 1-999 | 30-335 | 70-670 | 60db |

| XQM-1 | 220V 50HZ | 0.75KW | 1-9999 | 1-999 | 30-335 | 70-670 | 60db |

| XQM-2 | 220V 50HZ | 0.75KW | 1-9999 | 1-999 | 30-335 | 70-670 | 60db |

| XQM-4 | 220V 50HZ | 0.75KW | 1-9999 | 1-999 | 30-335 | 70-670 | 60db |

| XQM-6 | 220V 50HZ | 0.75KW | 1-9999 | 1-999 | 30-335 | 70-670 | 60db |

| XQM-8 | 220V 50HZ | 1.5KW | 1-9999 | 1-999 | 35-290 | 70-580 | 60db |

| XQM-10 | 220V 50HZ | 1.5KW | 1-9999 | 1-999 | 35-290 | 70-580 | 60db |

| XQM-12 | 220V 50HZ | 1.5KW | 1-9999 | 1-999 | 35-290 | 70-580 | 65db |

| XQM-20 | 380V 50HZ | 4KW | 1-9999 | 1-999 | 25-215 | 50-430 | 65db |

| XQM-40 | 380V 50HZ | 5.5KW | 1-9999 | 1-999 | 20-195 | 40-390 | 68db |

| XQM-60 | 380V 50HZ | 7.5KW | 1-9999 | 1-999 | 27-174 | 40-260 | 68db |

| XQM-100 | 380V 50HZ | 11KW | 1-9999 | 1-999 | 27-160 | 40-240 | 68db |

| Model | Capacity | Specification of milling tank | Qty |

|---|---|---|---|

| XQM-0.2 | 0.2L | 50ml | 4 set |

| XQM-0.4 | 0.4L | 50ml-100ml | 4 set |

| XQM-1 | 1L | 50ml-250ml | 4 set |

| XQM-2 | 2L | 50ml-500ml | 4 set |

| XQM-4 | 4L | 250ml-1L | 4 set |

| XQM-6 | 6L | lL-1.5L | 4 set |

| XQM-8 | 8L | 1L-2L | 4 set |

| XQM-10 | 10L | 1L-2.5L | 4 set |

| XQM-12 | 12L | 1L-3L | 4 set |

| XQM-20 | 20L | 2L-5L | 4 set |

| XQM-40 | 40L | 5L-10L | 4 set |

| XQM-60 | 60L | 10L-15L | 4 set |

| XQM-100 | 100L | 20L-25L | 4 set |

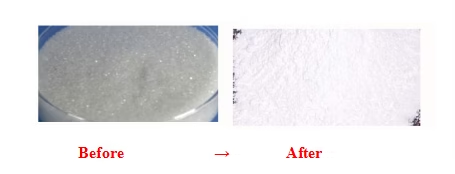

Grinding Sample