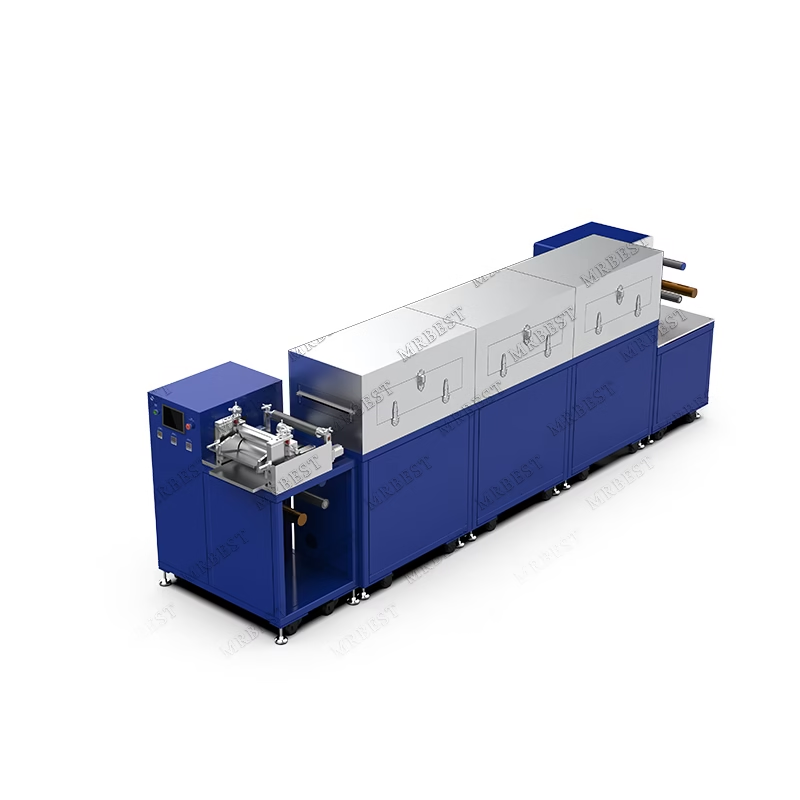

Model:MR-SY300-3J

Product Introduction

Features

Equipment Technical Parameters and Main Equipment Configuration

| No. | Item | Technical parameters |

|---|---|---|

| 1 | Suitable for System | Ternary, lithium iron phosphate, lithium cobaltate, lithium manganate, graphite, silicon carbon and other system battery positive and negative electrode coating process |

| 2 | Coating Type | Continuous and Intermittent Coating |

| 3 | Oven Section Number | 1 section 1m or 1.5m oven |

| 4 | Coating Speed | 0.5~1.5m/min, depend on heating |

| 5 | The Substrate Thickness | Aluminum foil (Al) : 8 ~ 30um copper foil (Cu) : 8 ~30um |

| 6 | Design Width of Roll Surface | 330 mm |

| 7 | Ensure Coating Width | within 280mm |

| 8 | Coating Roller, Cots | Φ120mm |

| 9 | Presser Roller | Φ80mm |

| 10 | Precision Coating | ±3um, except 10mm from the edge of the abnormal area |

| 11 | Weight Precision(mg/cm2) | Coating center value±1.0% |

| 12 | Suitable for Paste Viscosity | 2000~12000 (mPas) |

| 13 | One Side Dry Coating Thickness Range | 20-200μm |

| 14 | The Solvent Properties | Oily solvent NMP (s.g=1.033,b.p=204℃) Aqueous solvent H2O/NMP(s.g=1.000,b.p=100℃) |

| 15 | Suitable for Solid Content Range | 20~85% |

| 16 | Coating Size Accuracy(mm) | L≤±1 、W≤±0.5 |

| 17 | Precision of Front and Back Alignment (mm) | L≤±1 、W≤±0.5 |

| No. | Item | Technical parameters |

|---|---|---|

| 1 | Roller Mounting Structure | Install the steel frame firmly |

| 2 | Roll Surface Treatment | Metal aluminum roll surface oxidation |

| 3 | Tension Control System | Automatic control constant tension, tension range 0~50N, servo motor control |

| 4 | Rectify Way | Automatic EPC control, stroke 50mm |

| 5 | Winding Mode | The material coil is fixed with 3-inch air expansion shaft and air expansion shaft; |

| 6 | Maximum Unwinding Diameter | Ф250mm |

| 7 | Maximum Load Bearing of Gas Expansion Axis | 80Kg |

| 8 | Air-expanding Shafts Quantity | 1 |

| 9 | Main Drive Motor | Servo motor |

| 10 | Roll Surface Treatment | Metal aluminum roll surface oxidation |

| 11 | Doctor Blade | Double-sided comma doctor blade |

| 12 | Coating Roller (Steel Roller) | Hard chrome plating |

| 13 | Back Roller (Rubber Roller) | The surface is covered with imported epdm |

| 14 | Adjust Blade Clearance Height | Manual setting |

| 15 | Single Head Position | Installation and operation before drying path |

| No. | Item | Technical parameters |

|---|---|---|

| 1 | Oven Structure | Double layer independent heating, upper and lower arrangement |

| 2 | Oven Length | 1m or 1.5m/section |

| 3 | Material | SUS304 stainless steel |

| 4 | Temperature Control | Divided into normal working temperature control, over temperature monitoring and alarm protection control, and cut off the main heating power supply; The paragraphs are completely independent of each other |

| 5 | Heating Mode | Electric heating, hot air circulation structure |

| 6 | Single Section Oven Heating Power | 6KW |

| 7 | Inside Temperature of Oven | Design Max. 150℃, single section oven temperature difference ≤±2.5℃ |

| 8 | Blowing Way | Upper and lower air blowing, upper and lower air chamber share heating body |

| 9 | Structure of the Wind | Special mold is used to cut the air nozzle groove |

| 10 | Fan Control | Contactor control |

| 11 | Heating Control | Solid-state relay |

| 12 | The Fan Material | SUS304 stainless steel |

| 13 | Solvent Recovery System | Optional |

| No. | Item | Technical parameters |

|---|---|---|

| 1 | Rectifying Marching | Installation of drying outlet |

| 2 | Tension | Automatic control of constant tension |

| 3 | Installation Structure | Install the steel frame firmly |

| 4 | Winding Gas Expansion Axis Quantity | One-armed winding |

| No. | Item | Technical parameters |

|---|---|---|

| 1 | Master Control System | Touch screen, PLC, servo system |

| 2 | Mode of Operation | Manual, automatic, emergency stop; The whole machine can be operated before and after |

| 3 | Alarm Condition | When the device fails, the touch screen will display the corresponding correction screen |

| No. | Item | Technical parameters |

|---|---|---|

| 1 | Scraper | Circular jump ≤±1.5um, Ra0.4, straightness ≤±1.5um |

| 2 | Coating Roller(Steel Roller) | Circular runout ≤±1.5um, Ra0.4 straightness ≤±1.5um |

| 3 | Rubber Roller | Circle runout ≤10um, straightness ≤10um |

| 4 | Rectifying Deviation | ±0.2mm |