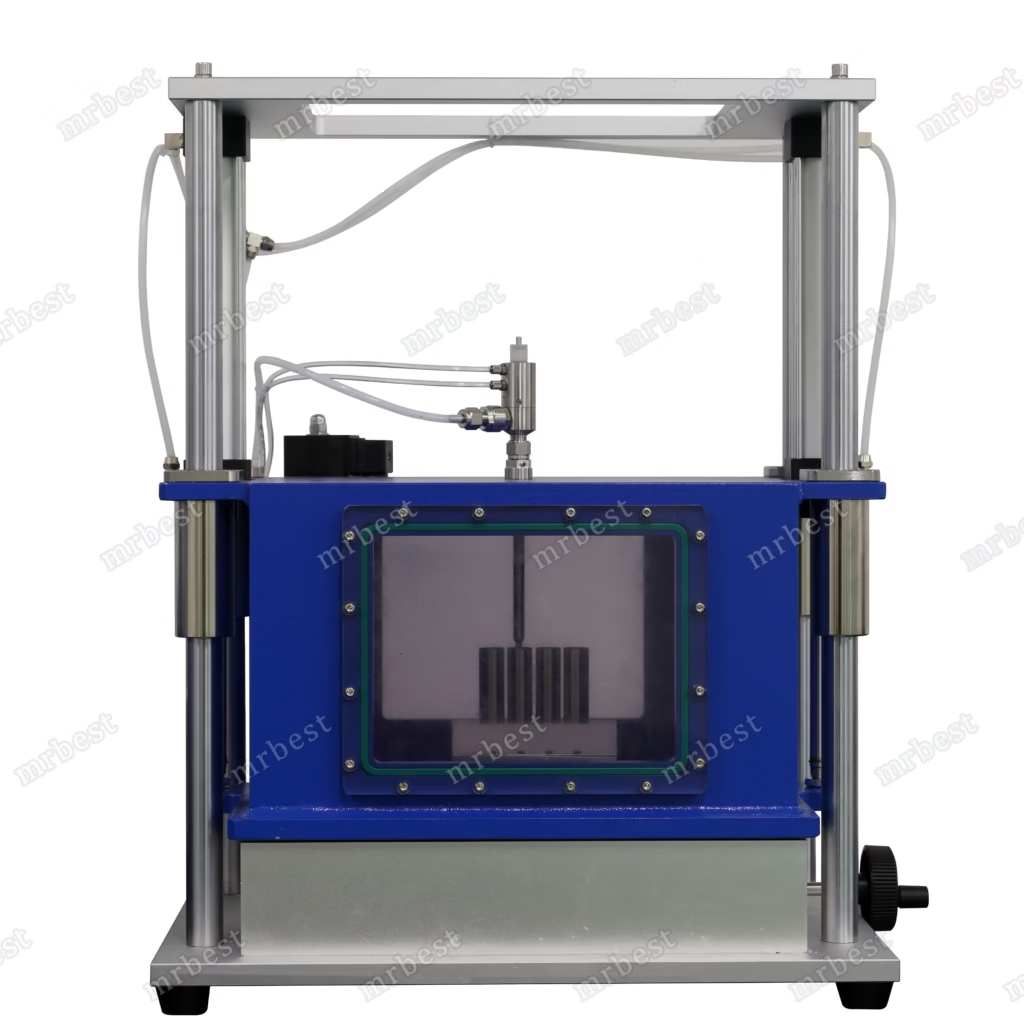

Model: MR-ZY65

Product Introduction

Features:

* One machine includes electrolyte filling and diffusion functions;

* High measurement accuracy and repeatability;

* Multi-station with high efficiency, accurate precision, convenient and reliable operation.

* Filling electrolyte after vacuuming, high efficiency, accurate accuracy, convenient and reliable operation;

*Injection accuracy±0.5%, injection volume 0.2 ml ~ 200 ml;

*The entrance and exit are connected by chemical resistant hoses;

*Can be operated in a glove box or dry room;

*The appearance is exquisite and beautiful, and the performance is stable;

*PLC, touch screen operation, flexible parameters, high automation program;

Equipment Main Configuration

| Model | MR-ZY65 Suitable for lithium battery products, cylindrical or pouch cell |

|---|---|

| Function | Injection and Diffusion |

| Cylindrical Range | Φ60, H100mm or less, according to the 18650 calculation standard with 4 stations, 4 notes at a time |

| Warranty | One year limited warranty with lifetime support |

| Range of Capacity | 0.2ml~200ml |

| Core Liquid Injection | 0.2g~200g |

| Injection Accuracy | ±0.5% |

| Exhalation Velocity | 6ml/s adjustable |

| In and Out Pipe | The liquid inlet pipe 6mm |

| Adjustable Stroke | Maximum X-axis stroke 0~80mm (center) |

| Material | Manufacture of stainless Steel 304 and 316 corrosion-resistant material in key parts |

| External Dimension | L510mm×W400mm×H650mm |

| Power Supply | AC220V/50Hz/0.5KW |

| Weight | 90kg |

Filling Workflow

*Put the product into the vacuum chamber;

*Press the start switch, press down on the transparent sealed upper cavity, so that the battery is in a sealed vacuum cavity;

* Vacuum, after reaching the vacuum degree and the set time, the liquid will be injected automatically. After the filling of one product, the hand-operated worktable will switch to another product to inject the liquid, multi-function analogy.

*Then the system will automatically degas still;

*After degassing still, take out the product to complete.

Remarks: The vacuuming time and degassing time can be set according to the situation.

Main Components of Equipment

*Cylinder and solenoid valve, vacuum components: SMC/Taiwan Airtac

*Guide slider: Taiwan Shangyin/Intime

*PLC: Display and control

*Touch screen: display control

*Analog vacuum gauge: Panasonic

*Motor: Lei Sai

Environmental requirements

*Ambient temperature: determined by the customer’s factory environment;

*Power supply: 220V, 50HZ, voltage fluctuation range: +10%~-10%;

*Compressed air: After drying, filtering and stabilizing: the outlet pressure is greater than 4.0kg/cm2; if it is placed in the glove box, the compressed gas used is the same as that in the glove box;

*Vacuum source: vacuum pump 2 liters/sec, above -98KPa, or pipeline vacuum (above -98KPa);