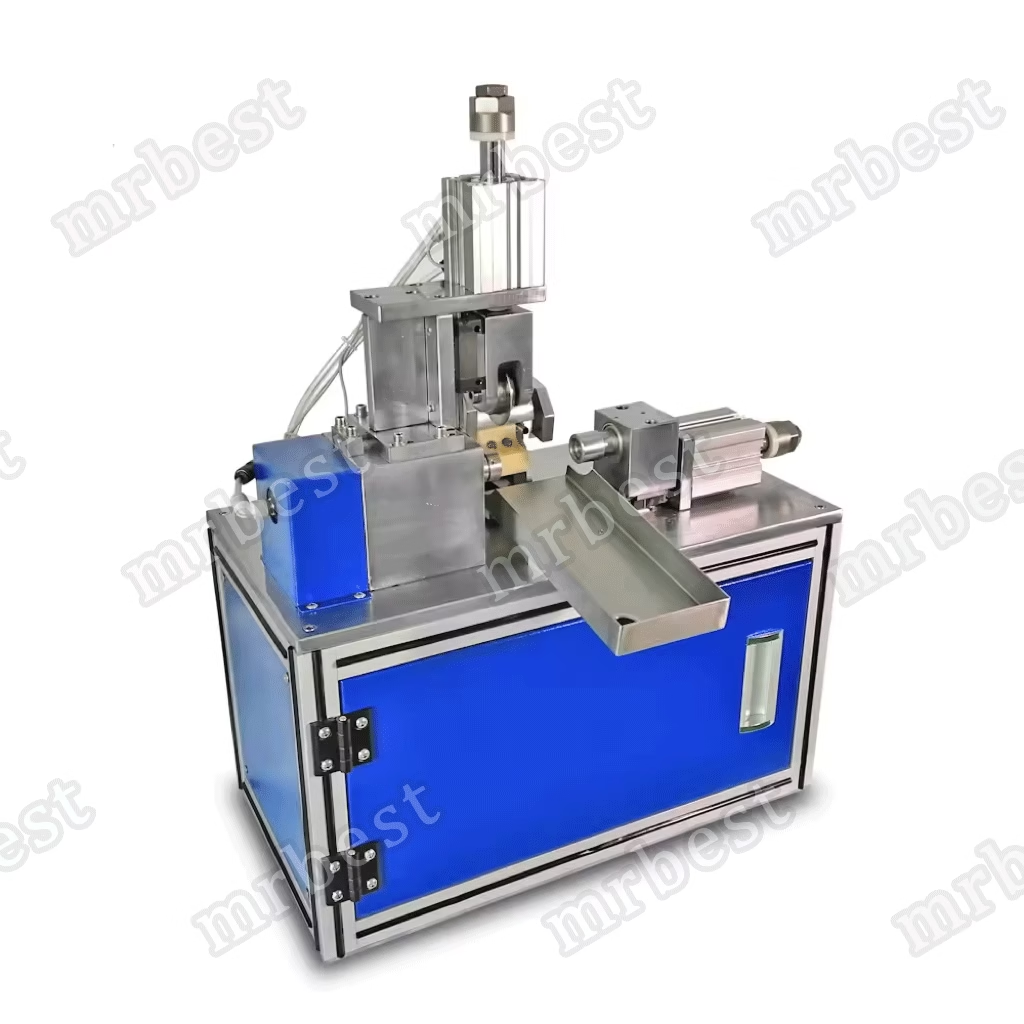

Model: MR-ZDGC700

Features:

* Automatic feeding and unloading, high efficiency, time saving, and labor-saving.

* Grooving size is adjustable, high accuracy and stable performance.

* Different grooving die can be changed for various of cylindrical cell grooving, like 18650,21700,26650.

* The machine is small size, exquisite in appearance and easy to operate.

* PLC & touch screen operation with high automation, and it is convenient to set various parameters.

Specifications

| Model | Automatic Grooving Machine For Cylinder Cell MR-ZDGC700 |

|---|---|

| Source Voltage | 110V-220V AC, 50/60Hz Single Phase |

| Power | 0.2KW |

| Grooving Mold | Standard 18650 cells rolling groove mold. Optional or additional for other battery types. |

| Grooving Wepth | 1.0-3.0mm adjustable |

| Grooving Width | 1.1-1.5mm (According to the thickness of roller knife) |

| Grooving Precision | ±0.1mm |

| Roller Knife Service Life | >3 million times |

| Production Capacity | 6PCS/min |

| Compressed Air | 0.5~0.7MPa |

| Dimension | L550 * W600 * H720mm |

| Weight | 50KG |

Maintenance Method

Precautions