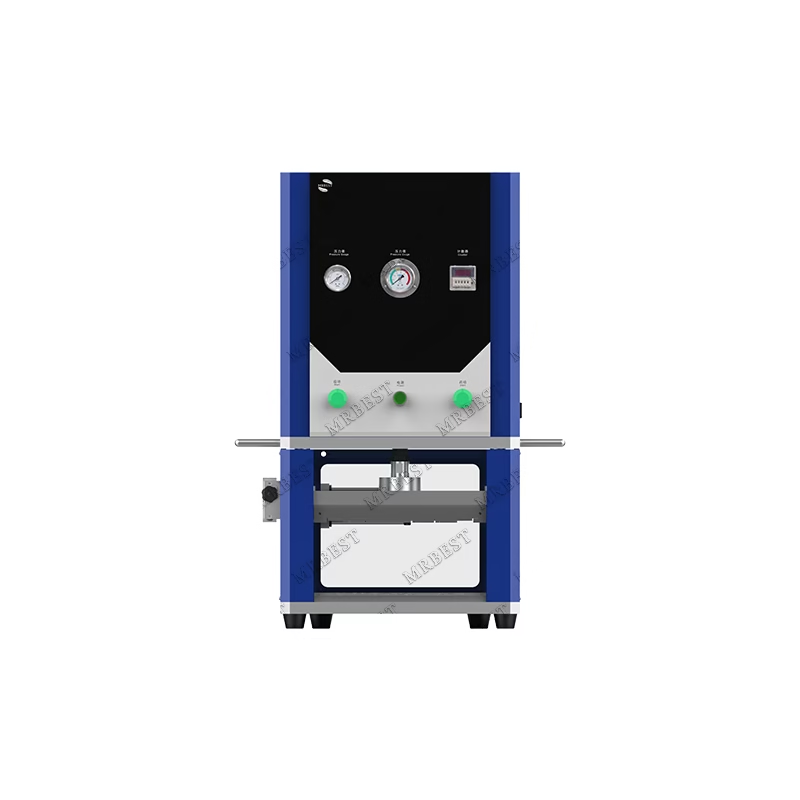

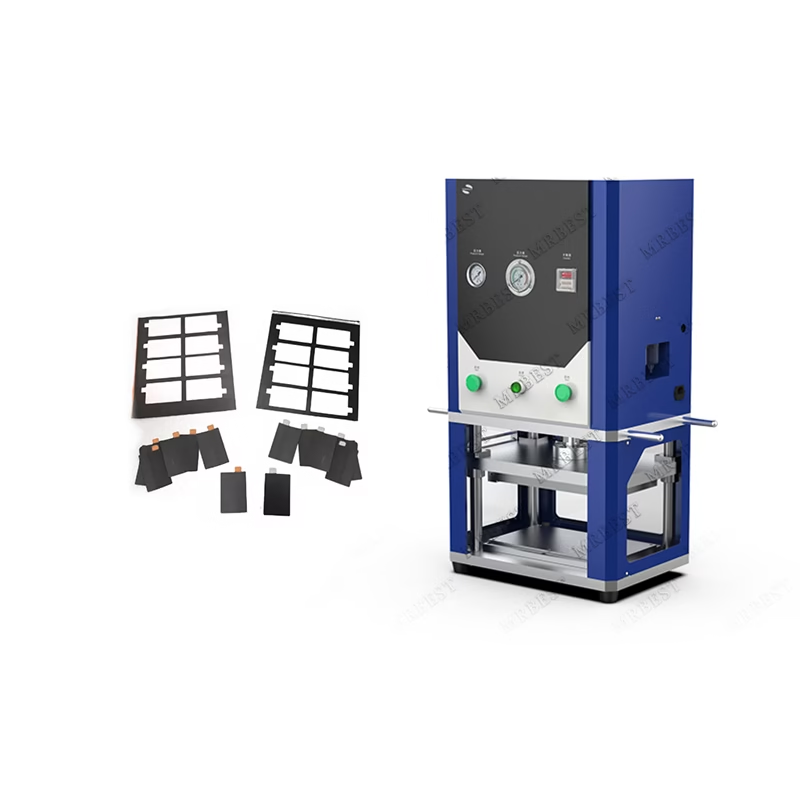

Model:MR-MQ280

Features

*Adopt infrared positioning device to accurately and conveniently locate and cut the pole piece;

* It is convenient and quick to change the die cutter;

*The die life is long, and the normal use is ≥30,000 times;

* There are no quality defects such as rough edge, clippings, or creasings;

*Between manual and fully automatic, the efficiency is 800 ~ 2000 pieces / hour;

(According to the size of the punched pole piece, you can punch 1 to 6 pieces each time)

* Four guide column structure, smooth sliding up and down;

*The equipment inlet has a safety protection light curtain, which is very safe to operate;

* Exquisite appearance, sheet metal adopts three-dimensional geometric design, simple and beautiful;

* Easy to operate, safe and reliable, small size;

Instructions

Specifications:

| Model | Precision Electrode Die Cutter MR-MQ280 |

|---|---|

| Infrared Positioning Device | Accurate and convenient positioning of the pole piece |

| Quality | Vertical burr ≤15μm, horizontal burr ≤20μm; |

| The life of the Die | Normal use ≥30,000 times |

| Maximum die cutting size | 280x180mm (Two standard electrodes (Cathode & Anode) cutting dies are included for immediate use, can be customized according to customer requirements) |

| Punching accuracy | ±0.1 mm |

| Air Cylinder | 3 tons Max. pressure Attention: If a gas cylinder is used instead of an air compressor, a two-stage pressure regulator must be installed on the gas cylinder to limit the pressure within the required working range for safe operation. |

| Die cutting stroke | 150mm |

| Gas-liquid air cylinder drive | punching force and punching speed adjustable |

| Production Yield | 800 - 2000 pieces of electrodes per hour |

| Warranty | One-year limited warranty with lifetime support Rusting and damage due to improper storage condition or maintenance are not covered by warranty |

| Safety Sensor | Built-in IR sensor (Safety Curtain) to protect against hand injuries during electrode feeding |

| Power supply | 220V/50Hz or 110V/ 60Hz |

| Max. Power Consumption | 100W |

| Compressed air | 0.5 Mpa to 0.8 Mpa |

| Dimensions | L700xW400xH950mm |

| Weight: | 165kg |

Equipment Composition

| 구분 | 내용 |

|---|---|

| Mechanical part | feeding guide part, upper die cutter mechanism, lower formwork mechanism, drive part, guide part, cover frame part, base part, discharge part, etc. |

| Electrical control device | Omron / Shanghai Second Industrial / Chint |

| Air cylinder: | Taiwan Jiuli / Yuxin / or equivalent brand |

| Pneumatic components | SMC / Taiwan Airtac |

| Bearing moving parts | NSK / Taiwan Baolong / domestic quality |

| Safety Sensor | SUNX / or equivalent brand |

Maintenance methods and precautions

1. Wipe the die cutter plate and guide the components frequently to keep them clean.

2. The linear guide of the guide bush of the ball guide column is lubricated and lubricated to keep the movement smooth.

3. If it is not used for a long time, wipe the surface of the moving parts of the mechanism clean and the surface should be protected by anti-rust oil.

4. Regularly check the screws, nuts, pins and other fasteners in all parts of the machine to prevent loosening and eliminate the machine.

Quality accidents and personal accidents.

Safety operation procedure

1. During the operation, it is strictly forbidden to extend the hand and other parts to the punching mold, the moving part of the guide bush of the ball guide, and the dangerous area of work to cause personal injury. Two or more people are not allowed to operate during operation to avoid accidental injury.

Remarks: With safety light curtain, electrical protection device and safety shield, all moving parts are inside the protective cover to ensure personal safety.

2. The external technicians and external design personnel cannot arbitrarily disassemble and debug the equipment.

3. Do not disassemble circuit components.1. During the operation, it is strictly forbidden to extend the hand and other parts to the punching mold, the moving part of the guide bush of the ball guide, and the dangerous area of work to cause personal injury. Two or more people are not allowed to operate during operation to avoid accidental injury.

Remarks: With safety light curtain, electrical protection device and safety shield, all moving parts are inside the protective cover to ensure personal safety.

2. The external technicians and external design personnel cannot arbitrarily disassemble and debug the equipment.

3. Do not disassemble circuit components.